Product Development

Product development at Smithmade Essentials begins with defining the core concept by using research, testing, and design to shape each collection into a cohesive system of scent, form, and visual language.

Product Concept Development

Product concept development began with establishing identity through scent, naming, and overall intent. From there, design decisions were made to support and express each concept across form, materials, and presentation.

While soap and candles followed the same conceptual approach, they were structured differently at the collection level. Soap collections operated within broader category frameworks. The Luxe & Lather collection served as a rotating space for more decorative, design-forward bars, while the Simply collection focused on soaps designed for everyday use.

Luxe & Lather

The original rotating collection of artisan soap featuring fun and fragrant designs.

Garden Collection

Designs inspired by nature, featuring hand-piped flower, vine, and leaf designs.

Simply

An everyday soap. Lightly scented bars designed with easy practicality in mind.

African Black

A standalone bar that fuses traditional and modern soap making. Every bar gives back.

Candle concepts were typically developed as distinct themes, with naming, scent exploration, and visual mood defining each product. Collections such as Autumn Moments, Dark Academia, and the Muse Collection reflect this approach.

Across all products, the narrative was defined early and carried through execution, allowing designs to remain cohesive while adapting to different formats, collections, and production realities.

Year-Round Soy Candles

Clean-burning, non-tox soy candles made with premium scents.

Seasonal Scents

A rotating collection of cozy fall and winter home fragrances.

Autumn Moments

A limited fall collection capturing the nostalgia of the season.

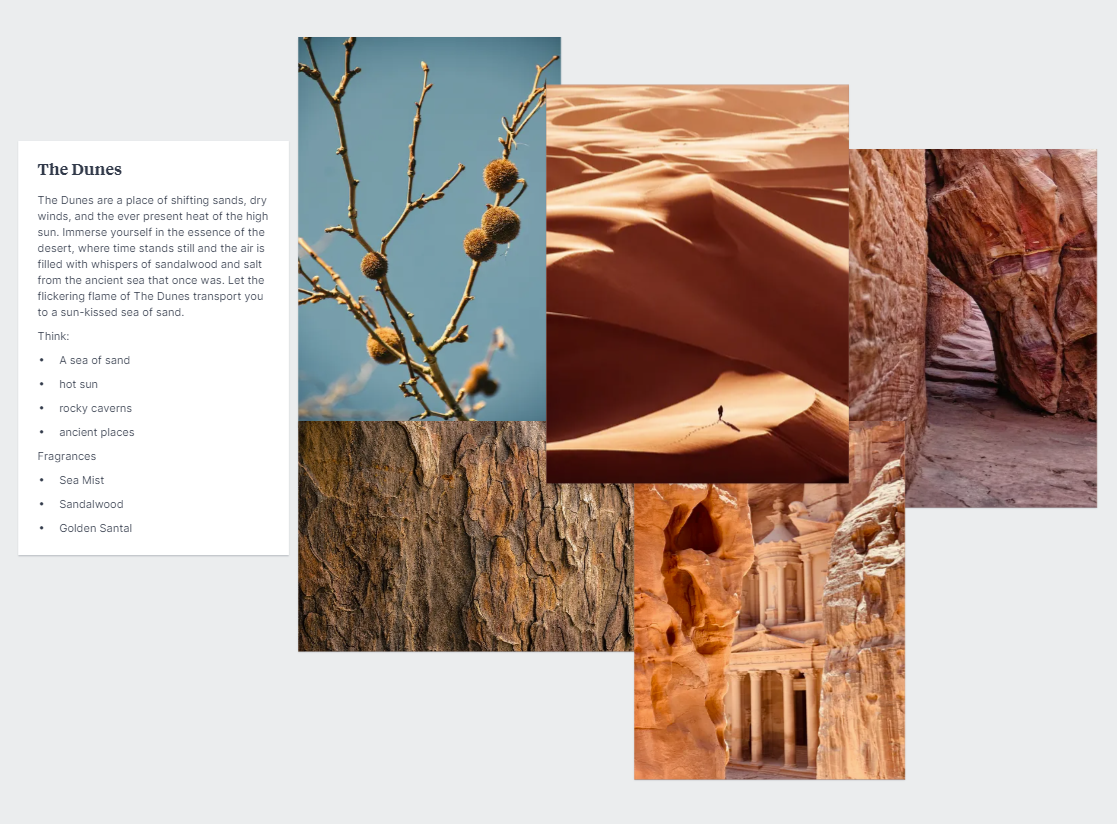

Muse Collection

A signature collection of original scent blends.

Sourcing

Sourcing played a critical role in product development, informing both design decisions and production feasibility. I evaluated materials and suppliers based on quality, availability, pricing, and lead times, balancing aesthetic goals with operational constraints.

This process involved researching vendors, comparing samples, and assessing how materials would perform across different product formats. Supplier selection directly influenced form, finish, and pricing across product formats, requiring trade-offs between aesthetic goals and production constraints.

Internal sourcing boards used to compare material options, finishes, and pricing while selecting suppliers.